FLOAT LEVEL SWITCH FLS

FLS series float level switch

Description

The magnetic-type level switches are available for external or internal mounting on tanks and are particularly suitable for all difficult working conditions (temperature and pressure). The ON/OFF-type outlet is normally used for alarm and shutdown functions. The level switches, depending upon their working requirements, are equipped with floats and displacers and possess flanged or threaded connections (UNI, DIN or ANSI).

• Pressure from 10 to 400 bar

• Temperature from -80°C to +540°C

• Specific weights from 0,3 Kg/dm3.

Furthermore level switches are available in simple float type and ultrasonic type.

Tecnical description

The FLS level switch is reliable solution to check and/or settle the level of the liquid in the drain water’s heaving stations, in the sewer water pumping station or industrial wasting, industrial waste, fuel diesel or hydrocarbon tanks, oil tanks, etc.

The switch doesn’t require any maintenance because there are no moving parts.

The switch is contained in a polyethylene casing which hangs free on a cable at the needed height.

It goes with the level variations of the liquid, therefore it closes or opens a contact by changing position (vertical/horizontal), in this way it sets going a signal or a pump.

A counterweight is eccentrically mounted, in order to hold the level regulator in the right position.

FSL level switch assures a good resistance at the main part of the chemical agents.

The float switch is filled with closed cells non-hygroscopic expanded polyurethane, eliminating all air, sealing the unit and completely surrounding the electric control switch.

The FLS Series level switch is available in two versions:

- Standard, with body of red colour and black cable in PVC-FROR, Mod. FLS-S

- ATEX approved, with polypropylene body and polyurethane cable of blue colour, Mod. FLS-A

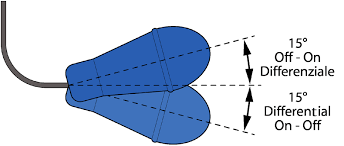

- Differential ~ 30°.

- The electrical cable is fixed inside the tank or by employing the proper hooks and redances.

- Power supply cable not replaceable, in case of damage the entire device must be replaced.

- The height of the switch determined the set point.

- For starting and stop of each pump, n°2 FLS level switches should be employed.

- A version approved for drinking water is available on request.